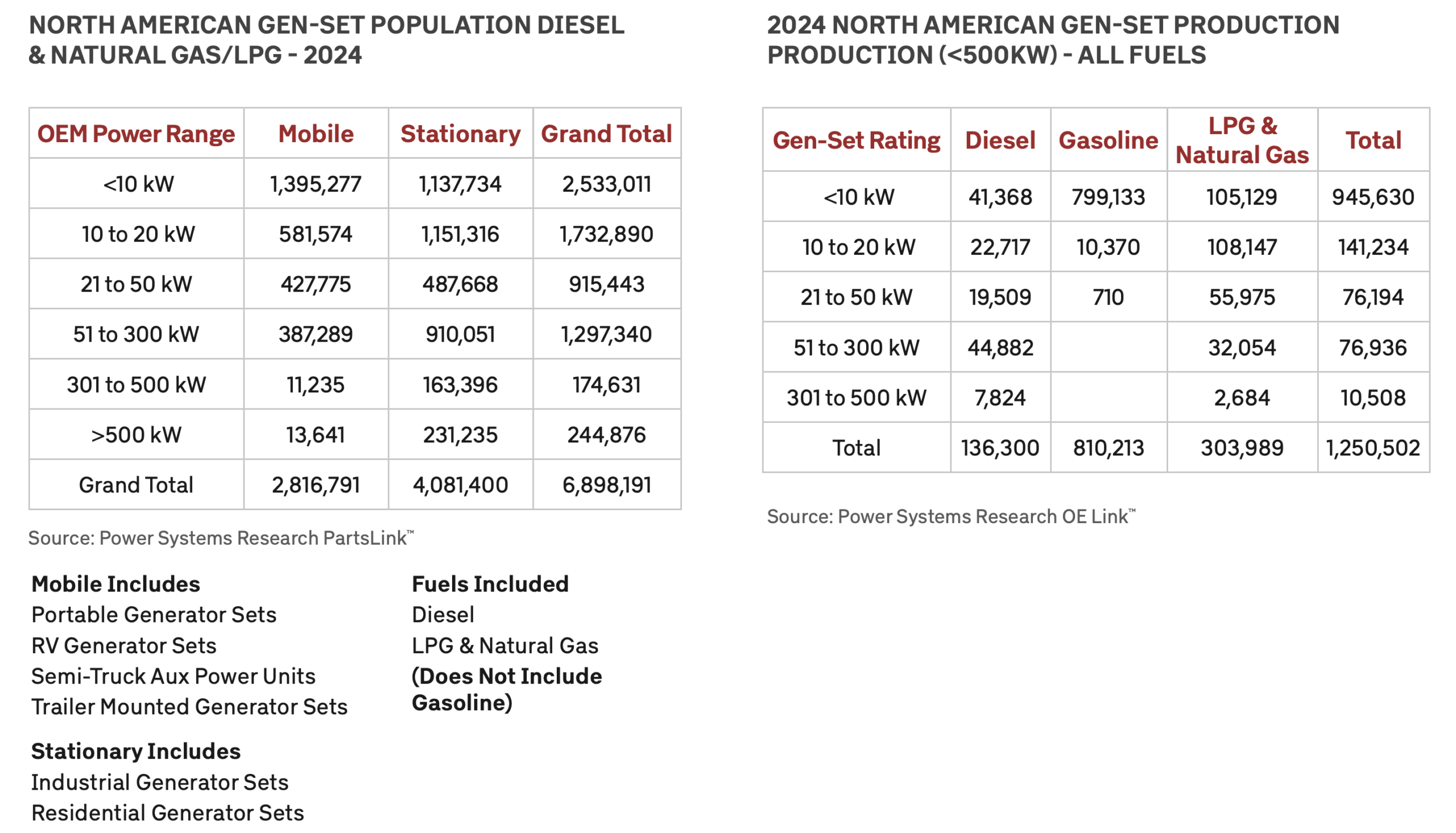

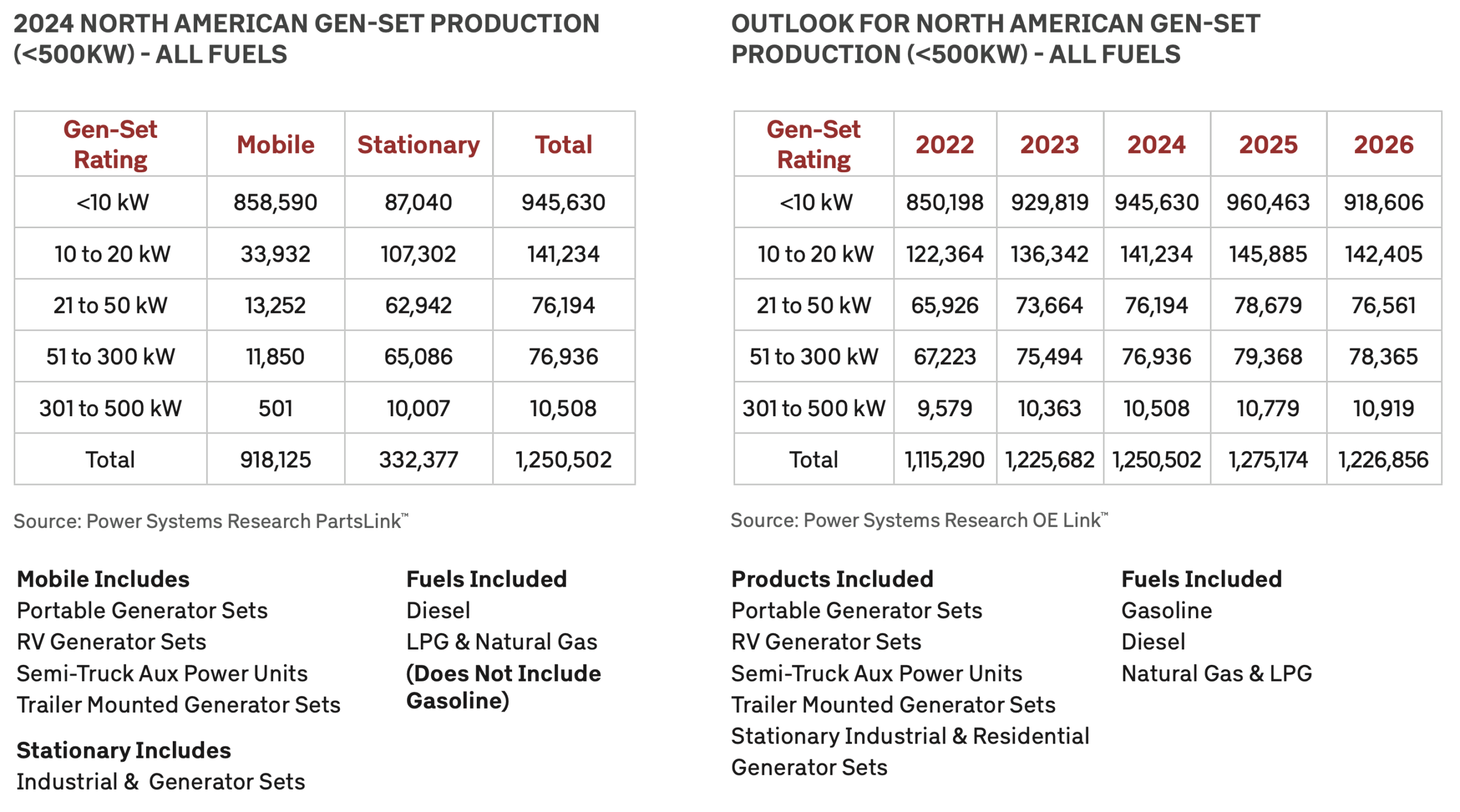

| Why Service & Monitoring Will Matter More Than Ever As we look ahead to 2026, one thing is clear: the generator industry is entering a new phase—one defined less by equipment sales alone and more by long-term service, reliability, and intelligent monitoring. Over the past several years, genset production continues to accelerate across residential, commercial, and industrial markets primarily driven by grid instability, rising utility costs, data center expansion, extreme weather events, and energy security concerns. This expanding installed base is reshaping the industry’s priorities. Genset Market Overview Power Systems Research provides comprehensive data on our industry, including generator production, generator in-service population and growth trends. Thank you to Joe Zirnhelt, President of Power Systems Research, and his team for providing the details below (www.powersys.com). |

| What the Data Shows At the end of 2024, there are over 6 million existing generators (not including gasoline portables). If you remove from the data the small portable diesels, LP generators, RV generators and semi-truck auxiliary power units, there are still over 5 million existing stationary and towable generators in North America that require service. On top of that, there are over 350,000 generators in these categories being produced and sold each year adding to that population. More generators in the field means a dramatically higher demand for generator service. Every new unit sold adds 10, 15, even 20+ years of required maintenance, testing, repairs, and compliance inspections. As generator populations grow, service intervals tighten, parts consumption increases, and skilled labor demand rises. By 2026, many service providers will find that maintenance, not new equipment, represents the most consistent and scalable revenue opportunity in the market. Generator Monitoring Becoming More Important Than Ever With thousands of additional standby and prime power generators operating in critical applications, manual checks alone are no longer sufficient and unsustainable. Remote monitoring enables proactive maintenance, faster fault detection, reduced downtime, and improved compliance. Generator owners increasingly expect real-time visibility into generator health, run status, alarms, and service needs. With that in mind, if you aren’t pushing monitoring for all of your customers, the time to start is now. Key Benefits – Generator Owner Peace of Mind – Customer Loyalty & Satisfaction – Automated Communication to Your Customers – Reduce Vehicle Expenses – Fast, Proactive Service Response – Service More Customers Per Technician – Improve Efficiency & Productivity – Increase Bottom Line Profit – Improve Reliability – Increase Top Line Revenue – Reduce Unbillable Service Trips – Differentiate from Your Competition Types of Monitoring Systems Available There are many brands and types in the generator monitoring space these days, but one thing is consistent, there are two major categories for monitoring. The first type is Essential Monitoring. This covers the basics from generator run/stop, exercise tracking, battery level, engine run hours, extended run times, common fault, etc. For most residential generators, this is the ideal level of monitoring. The other type is Advanced Monitoring. This category is designed around Modbus which is the generator controller language protocol. When you track Modbus data, you can track dozens of data points from analog parameters like volts, amps, frequency to individual fault alarm conditions. If you’re looking to deep dive into the generator information, then advanced monitoring is the way to go. To determine the right monitoring approach, many service providers begin by evaluating factory/OEM offerings alongside independent monitoring solutions. While OEM systems can be effective in specific use cases, independent platforms often provide greater flexibility across mixed fleets, longer product lifecycles, and broader data access. This is where experienced monitoring partners like Power Telematics play a valuable role, offering solutions that work across multiple generator brands and controller types, scalable monitoring levels, and deep industry expertise that supports service teams long after installation. The right partner doesn’t just deliver data; they help turn monitoring insights into more efficient service, stronger customer relationships, and long-term reliability. Redefining Value in the Generator Industry The generator market is growing strong, and there’s a major opportunity to grow your service business. Service companies who heed the shifting demand toward service and monitoring will unlock faster growth avenues, strengthen customer loyalty, and enhance operational outcomes for end users. Invest in service capabilities. Invest in monitoring technologies. Invest in people. Because in an increasingly power-hungry world, reliability is the product customers care about most. |